Posted by Patti Gander, AssuredPartners How has manufacturing progressed from the first industrial revolution (Industry 1.0) to where it is today, commonly referred to as Industry 5.0? The industry has come a long way since the late 18th century, when the Industrial Revolution started, and it continues to evolve. Read AssuredPartners’ full article here: The Manufacturing Evolution from Industry 1.0 to industry 5.0

Revolutionizing Manufacturing: How AI is Transforming the Industry

Posted by Patti Gander, AssuredPartners Artificial Intelligence (AI) is in its infancy for use in the manufacturing sector. Manufacturers who have adopted it as a tool are finding ways to improve their operations, reduce costs, enhance product quality, and drive innovation. Here are some common applications of AI in manufacturing: Read AssuredPartners’ full article here: Revolutionizing Manufacturing: How AI is Transforming the Industry

Data Analytics and AI in Manufacturing

Posted by Patti Gander, AssuredPartners The manufacturing industry continues to evolve and transform rapidly. The transformation and growth have been referred to as Industry 4.0 or the Fourth Industrial Revolution. With this transformation, manufacturers are moving towards a fully integrated manufacturing environment called a connected factory, as part of the Industry 4.0 transformation. Read AssuredPartners’ full article here: https://www.assuredpartners.com/blog/detail/bid/980/manufacturing/data-analytics-and-ai-in-manufacturing

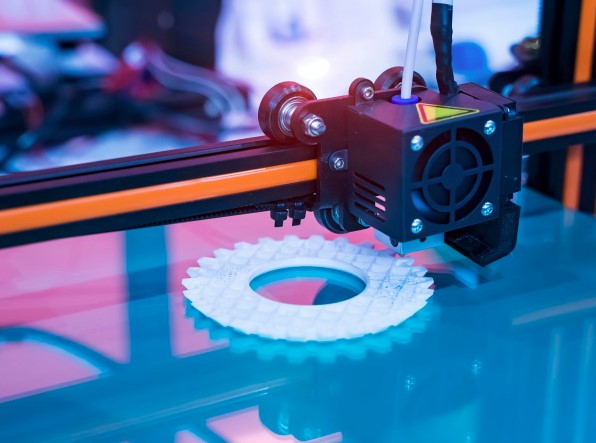

Additive Manufacturing

Posted by Patti Gander, AssuredPartners Additive (3D printing) has transformed the manufacturing industry. Its capabilities have reshaped traditional production methods and are set to bring forth even greater benefits. In this article, we explore how this technology has impacted and continues to shape the landscape of modern manufacturing. Rapid Prototyping: 3D printing allows engineers to rapidly prototype designs. Rapid prototyping will enable engineers to discover potential design issues before finalizing and moving the product from design to production. Inventory Reduction: 3D printing allows manufacturers to produce items on demand. Inventory levels of finished products will not be needed since the product is printed when required. Using on-demand product manufacturing aligns with the “just in time” manufacturing approach to inventory. Customization and Personalization: As …

Manufacturing and Environmental Sustainability

Posted by Patti Gander, AssuredPartners The manufacturing sector plays a significant role in overall environmental impacts. The industry consumes natural resources on a global scale, as well as waste generation and greenhouse gas emotions. The manufacturing industry must seek methods to reduce its impact to promote long-term sustainability. Here are some key aspects and strategies related to manufacturing and environmental sustainability: Resource Efficiency: The manufacturing industry has adopted Lean Manufacturing as a business strategy. At its core, Lean focuses on waste elimination throughout the entire system. Resources consumed in manufacturing are not only human resources but include energy, water, and raw materials. Lean methods address process optimization for all resources consumed in the process, including ways to reduce excessive consumption, considered …

Increased Adoption of Automation and Robotics in the Manufacturing Industry

By Patti Gander for AssuredPartners The manufacturing industry has continued incorporating automation and robotics into its manufacturing processes. Although there are several reasons for this transition, some key driving factors are increased productivity, greater efficiencies, and overall improved quality. Additionally, the manufacturing industry, like many other industries, struggles to find people to fill the job vacancies. As robots become more flexible and collaborative, they are being implemented to work cooperatively and safely with operators. Robots are capable of handling complex tasks and can easily be adapted to changes in production requirements. Robots are even being integrated with other technologies, further enhancing their capabilities and enabling real-time data analysis for optimization. Included in the manufacturing industry’s move towards a greater emphasis …

Manufacturing in 2023 and Beyond

By Patti Gander for AssuredPartners Manufacturing continues to be a topic of discussion across the United States and globally, as the industry still struggles with supply chain disruptions and a shortage of skilled labor. Although there is no crystal ball to accurately predict what will be some of the driving forces in manufacturing, here are some potential key factors facing the industry. 1. Increased adoption of automation and robotics: The shortage of skilled labor and the ever-increasing demand for higher output, lowered costs, and increasing expectations of product quality mean manufacturers will likely look at automation and robotics as a solution. Where automation and robotics have been adopted by the larger manufacturing companies, mid-sized and small manufacturers are beginning to adopt these …

What is the Manufacturing Skills Gap?

By Patti Gander for AssuredPartners The manufacturing skills gap has been a topic for several years and that gap continues to expand. What is the manufacturing skills gap? The skills gap refers to the disconnect between the skills and knowledge that employers in the manufacturing industry require, and the skills possessed by the current workforce. The gap is created by several factors, including: An aging workforce Advances in technology Population growth is decreasing causing more competition for the available workforce Manufacturing is not often thought of as a career path Changes in the nature of manufacturing jobs. As older workers retire, they take their skills and knowledge with them, leaving a gap that is difficult to fill. At the same …

What Manufacturers Need to Know About Loss Control

Q&A with Ryan Overly, Risk Control Consultant with Murray, an AssuredPartners company By Jenn DeWalt, Business Development Specialist, Murray This is the fifth and final part of a series on safety considerations for manufacturing companies: The first part of the series covered specific loss control considerations manufacturing companies need to consider regarding workers’ compensation and keeping their employees safe. The second part covered information on the top causes of loss in the manufacturing industry. The third part of the series covered valuable tips on keeping drivers and fleets safe. The fourth part covered details on both the virtual and online safety techniques that Murray offers for their clients. The fifth part of the series addresses specific risk management and loss …

What Manufacturers Need to Know About Loss Control

Q&A with Ryan Overly, Risk Control Consultant with Murray, an AssuredPartners company By Jenn DeWalt, Business Development Specialist, Murray This is the fourth part of a series on safety considerations for manufacturing companies: The first part of the series covered specific loss control considerations manufacturing companies need to consider regarding workers’ compensation and keeping their employees safe. The second part of the series covered information on the top causes of loss in the manufacturing industry. The third part of the series covered valuable tips on keeping drivers and fleets safe. Almost $1.2 billion is paid out every week in our country for workers’ compensation claims. Manufacturers in particular may be experiencing what often seem like small incidents, but those small …

- Page 1 of 2

- 1

- 2